Specifying ‘Prefinished’ European Birch Plywood can help save time, money and reduce waste!

In this era of increasing costs, it’s now more important than ever to find ways to save both time and money in the construction and joinery sectors. DHH Panel Products can help companies save ‘time and money’ as they offer a wide range of structural, high-quality, European (Latvian and Finnish) Birch plywood which is already prefinished with a decorative overlay.

By using a prefinished-board it can help reduce the need for priming, painting, laminating or lacquering and can save both time and additional costs. DHH also offer (made to order only) CNC-machined panels or components direct from plywood mills. Panels can be pre-drilled for example, meaning they are ready-to-use or fix, thus reducing overall installation time – another important factor when assessing material choice for a project.

Using overlaid/pre-finished panels means there is also less waste to dispose of (fewer empty paint tins, laminate off-cuts, empty cartridges etc.) as reducing waste on site or in the workshop assists with cutting costs and reduces the amount ultimately sent to landfill. By using ‘Prefinished Birch Plywood’ not only does it help save time and money, but it’s also an ‘eco-friendly’ material.

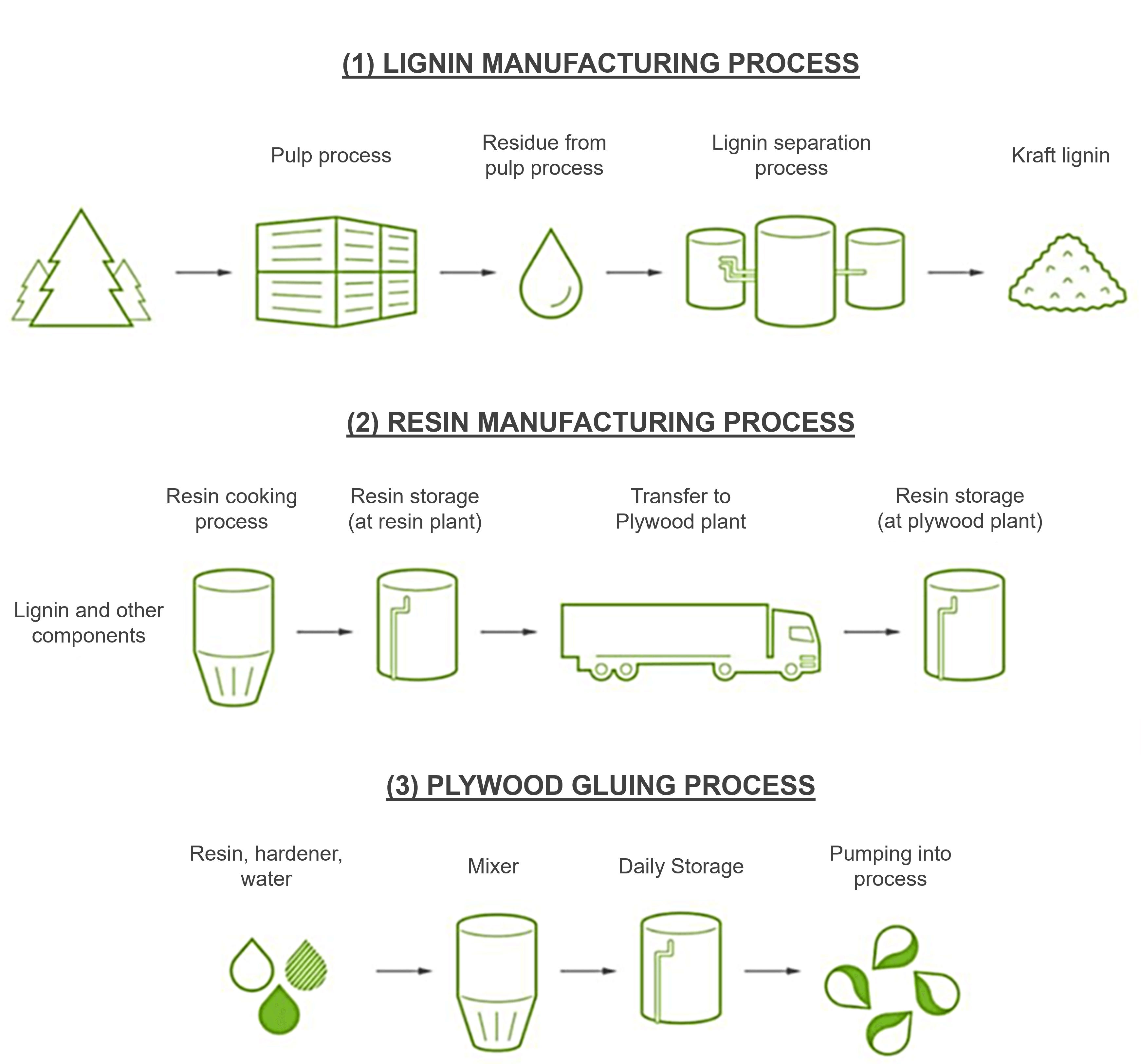

We source sustainable birch plywood from ‘Riga Wood’ in Latvia, which is bonded with an innovative, environmentally-sustainable adhesive, derived from Lignin, a naturally occurring strengthening substance found in all timber. Even in these more difficult times, DHH Panel Products has continued to look at ways to improve sustainability and were one of the first plywood importers to introduce this new adhesive as standard for its raw and overlaid birch plywood.

We also stock a range of ‘Pre-lacquered’ birch plywood which can be used for decorative wall panelling, kitchen carcasses, shelving, van-conversions, joinery and furniture and because it’s pre-lacquered at the mill in Latvia – all the hard work and preparation has been done, so boards only need cutting to size or CNC machining. It really can save a great deal of time and reduce waste-material – which is so important today (when construction costs are spiralling) as consideration for the environment must to be taken into account when looking at material specification options.

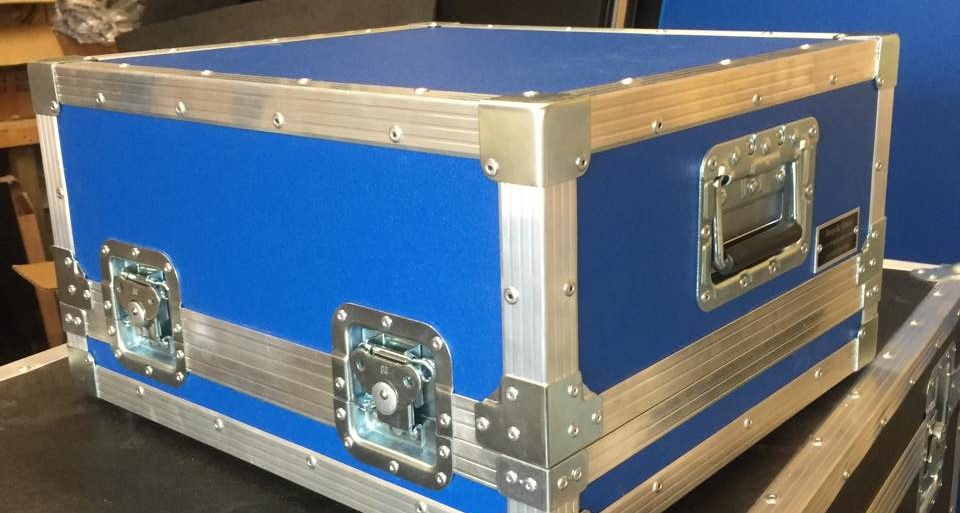

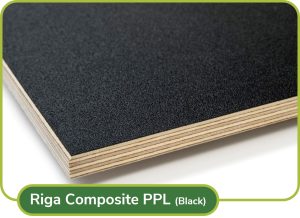

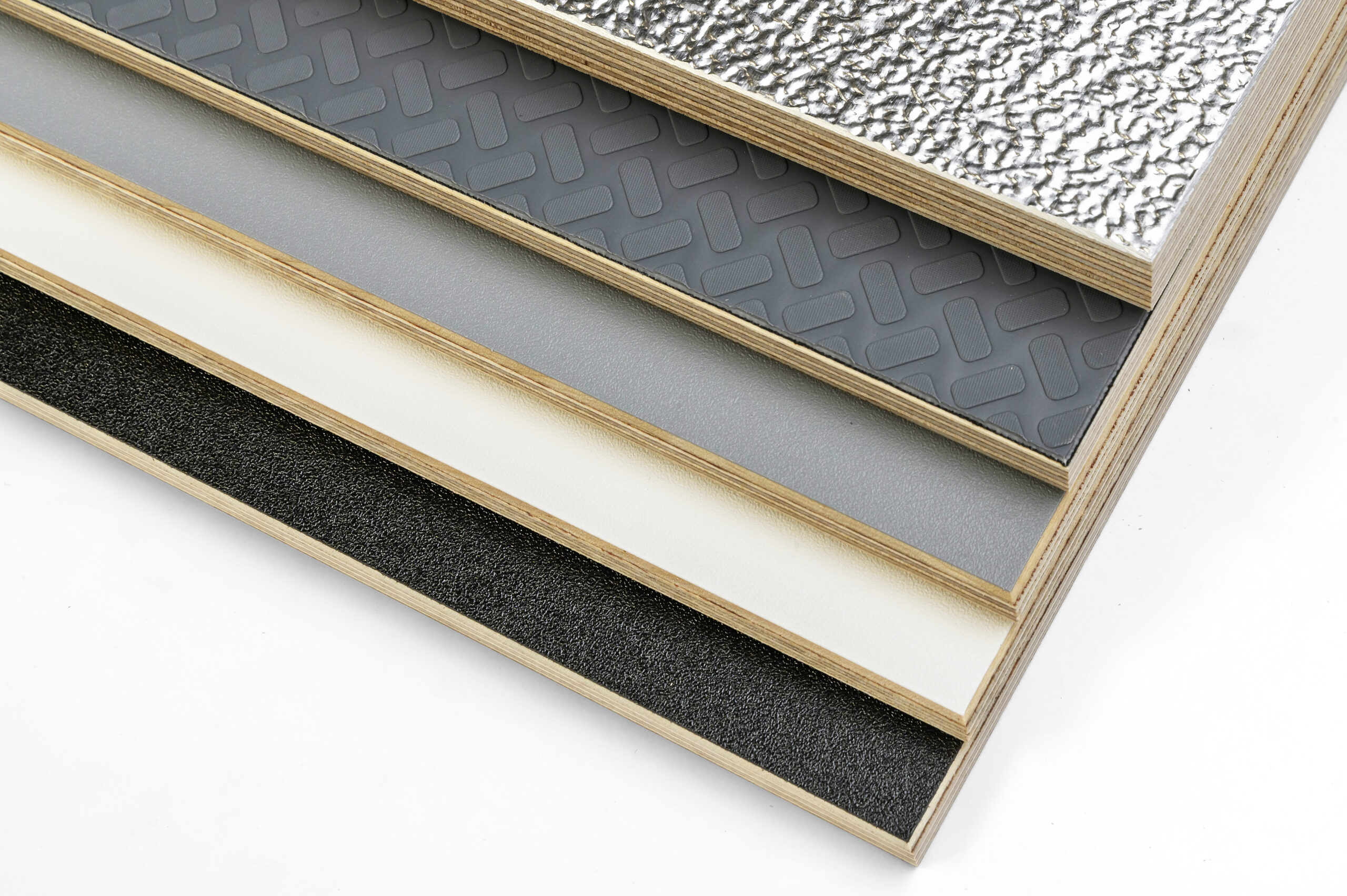

Other overlaid-birch panels stocked at DHH include ‘White Melamine-faced Birch Plywood’ and ‘Riga-Composite and Koski-Futura PPL’, a ‘Polypropylene-faced’ Birch plywood which can be used for different applications and offers the benefit of being ready-to-use without the inconvenience of needing to bond or paint it. White Melamine and PPL-coated birch plywood are suitable for interior joinery work, carcassing, furniture and offer the consumer robust, hygienic, but easy-to-clean surfaces.

These materials are also easy to machine and work, PPL birch for example, is suitable for CNC machining as it does not ‘chip’ or ‘break-out’ like some more brittle materials can. This can be of great benefit when machining multiple components as will help to reduce rejects and wasted panels. So prefinished birch plywood offers multiple benefits for the client, consumer and contractor and has the added benefit of being sourced from truly sustainable European forests, where forest management has been practised for well over one hundred years.

Prefinished, European Birch Plywood is the ideal option for demanding projects which require high-quality materials, but also have a commitment to being more environmentally-focused, as using this type of material can help to reduce waste, whilst also helping to save on time and cost.

Other prefinished birch plywood available from DHH Panels stock includes, Smooth Phenolic-film faced, Slip-resistant Mesh (Tex ) and Heksa Plus pattern phenolic, Grey Primed and bespoke items, such as CNC and painted panels are aslo available to order, MOQ’s may apply.

Feature Image: Example of ‘Riga Composite’ PPL and Aluminium options – available in a range of sizes and coloured overlays, some from stock, others available on request.

*Steph Plaster is one of our resident Technical Plywood Experts; and has a wealth of experience and knowledge around using Plywood for advanced applications.