There are two basic plywood standards that are of most relevance; one specifically for wood species durability (EN 636), and another for the glue line (EN 314).

These two standards should be considered together when selecting the most appropriate product. This DHH Explainer will help you understand the two standards better; and help you make a more informed choice.

>> EN 636 Standard: Wood Species Durability

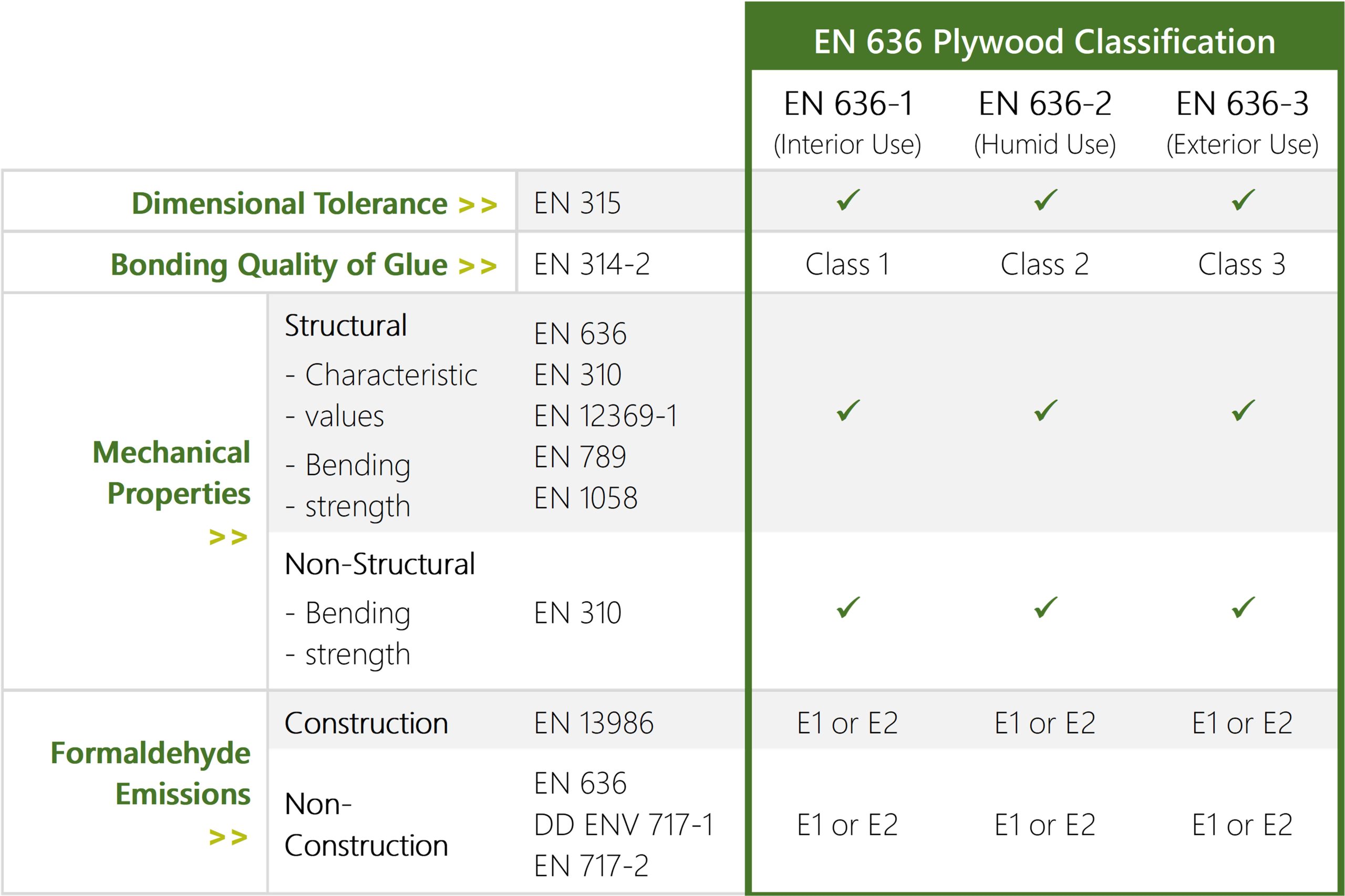

In respect to constructional plywood, the uniform standard for wood products (EN 13986) requires that each plywood species must comply with one of the three below performance classes within EN 636. Each now has its own EN-636 identifying code, for easy reference:

- Class 1 Wood Species (Now EN 636-1): Class 1 Wood Species are suited for interior use only. These types of plywood products will likely deteriorate and break up if used within a humid environment; even with treatment.

– - Class 2 Wood Species (Now EN 636-2): Class 2 Wood Species are typically suited for humid conditions. This includes washrooms and locker rooms. These products can be used in exterior application too, but must be appropriately treated or covered on any exposed faces and edges.

– - Class 3 Wood Species (Now EN 636-3): Class 3 Wood Species are suitable for all outdoor application. These products should not break up in exterior weather conditions, even when fully exposed to the elements. You must however ensure that all exposed edges and faces have been treated accordingly.

Compare the different EN 636 types with other relevant EN standards:

>> EN 314 Standard: Bonding Quality of Glue

The bonding quality of the glue used in plywood production has also been divided into three classes. Each class of glue has its own EN-314 code. This will help you identify which type of glue your product is using:

- Class 1 Glue (Now EN 314-1): Class 1 Glues are mainly designed for dry indoor use only. These glue products have little protection to humidity, and are likely to delaminate when exposed to wet & humid conditions.

– - Class 2 Glue (Now EN 314-2): Class 2 Glues can be appropriately used in protected exterior applications; . This includes areas of high humidity such as washrooms. These products have limited properties, but can resist moderate humidity.

– - Class 3 Glue (Now EN 314-3): Class 3 Glues can be used in full exterior applications, as long as all exposed edges and faces have been treated accordingly. These products are capable of resisting most types of weather conditions over a sustained period of time. This standard replaces WBP grade.

>> Important Points to Remember

For a plywood panel to be at its most effective, it’s important to consider both the quality of the wood species AND the bonding quality of the glue:

- If you’re looking to use a product within an indoor humid environment, ensure that both the wood species & glue are at least Class 2.

– - For outdoor application, ensure that both the species and glue are at least Class 3 (or Class 2, if you intend on treating any exposed areas). Most exterior grade plywood and Marine Plywood meet Class 3 requirements.

– - It’s recommended that all plywood used in exterior application should be face and edge sealed prior to use. This will help to preserve the longevity of the product.

Need further assistance? Our team of Product Experts are on hand to help. Give us a call on 01708 864245, or send us an email at sales@dhhpanelproducts.co.uk.